sulfur and phosphorus content of gray cast iron

Among the gray cast iron, especially the higher grade gray cast iron, it is not that the lower the sulfur and phosphorus, the better, but an appropriate amount, so do you know how to control the content of sulfur and phosphorus of gray cast iron, today let us tell you.

The effect of sulfur on gray cast iron

(1)Because sulfide can be used as the base of eutectic graphite nucleation, and at the same time can inhibit the growth of eutectic cluster, but sulfur is an element that promotes the formation of white mouth in cast iron, therefore, an appropriate amount of sulfur is beneficial. From the perspective of reducing white mouth, when the sulfur content is 0.041%, the white mouth width is the smallest, whether it is inoculated or not, but the number of eutectic clusters is in an intermediate state.

(2)The test of the influence of sulfur on the mechanical properties of gray cast iron shows that whether inoculated or non-inoculated cast iron, when the content of sulfur not more than 0.04%, the brinell hardness increases rapidly with the increase of sulfur content, when the content of sulfur more than 0.04%m the hardness is the increase slows down, when the sulfur content is 0.06%, there is 40% pearlite in the matrix, and when the sulfur content is 0.04%, the pearlite content is 100%. Regardless of the inoculated or non-inoculated gray cast iron, the tensile strength is SO, it reaches the maximum value between 0.04-0.06%, and the relative hardness reaches the minimum value, at the same time, experiments have shown that when the sulfur content of gray iron is less than 0.04%, it is difficult to make Sr-containing FeSi play a role in incubation.

The effect of phosphorus on gray cast iron

(1)For thin-walled refrigerator compression shell castings, although its chemical composition is specified as Carbon:3.3-3.7%, Silicon:1.8-2.7%, Mn:0.3-0.7%, and phosphorus and sulfur not more than 0.15%, preferably phosphorus not more than 0.12%. Because phosphorus forms binary or ternary phosphorus eutectic in gray cast iron, and the melting point of these eutectic is lower than that of the matrix, it is easy to cause defects such as shrinkage and cold cracking in castings. However, phosphorus is not as low as possible, but should be controlled within a certain range. Phosphorus can weaken the mechanical and chemical adhesion of gray iron castings, so that the surface of the castings can be smooth and clean. Production practice shows that when the phosphorus content is 0.02-0.04%, sand sticking occurs in castings, and when the phosphorus content is increased to 0.09-0.12%, sand sticking to castings disappears, and the sand cleaning time of castings can be reduced by 35%. Why does phosphorus reduce the sand stickiness of castings? Sand sticking of castings mainly occurs at the hot joints, especially the hot joints of the inner cavity, rather than at the position where the hydrostatic pressure of the iron is the highest, that is, the lower part of the casting. Sand sticking occurs in the solidification process of castings, and it is caused by graphitization expansion caused by eutectic transformation of cast iron. The measurement of the phosphorus content in the molten iron and the penetration depth of the molten iron shows that the higher the phosphorus content, the smaller the penetration depth of the molten iron into the sand grains. In addition, the serious sand sticking of the casting will lead to strengthened shot blasting, which will further harden the surface of the casting and deteriorate the processing performance.

(2) Phosphorus is used to improve the wear resistance and fluidity of castings. For castings that require high wear resistance, such as machine tool rails, piston rings, cylinder liners, etc., phosphorus-containing alloy cast iron, such as P-Cu-Ti cast iron, is also used with the phosphorus content of 0.35-0.65%; the purpose of adding phosphorus is to use the wear resistance of the phosphorus eutectic to achieve the purpose of reducing wear. For some thin-walled castings and artistic castings, in order to make the contours of the castings clear and the surface smooth, an appropriate amount of phosphorus is usually added. For example, sewing machine castings contain phosphorus of 0.3%, radiators contain phosphorus of 0.4-0.5%, and some artistic castings contain phosphorus as much as 1.5%.

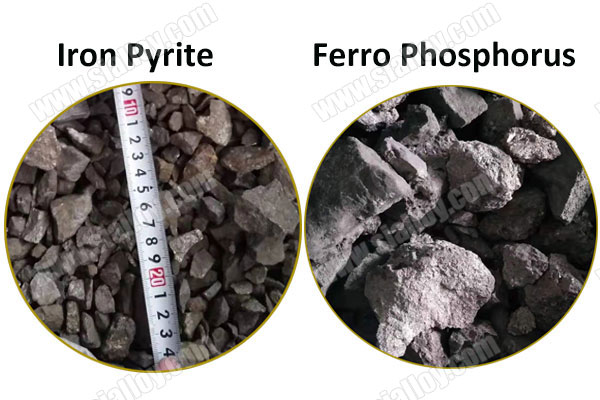

In order to produce high quality gray cast iron, Anyang Huatuo Metallurgy would like to provide more help, we can provide high quality iron pyrite and ferro phosphorus, we keep the high quality of raw materials to help you for high quality gray cast iron.

中文

中文