Blog

Solid calcium cored wire is to break the metal calcium into a certain particle size ( or make calcium wire or calcium stick), then use cold rolled low carbon steel strip to wrap it into a composite material with any length....

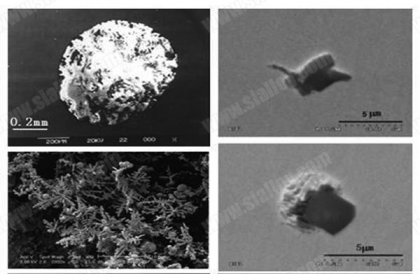

Non-Metallic Inclusions in Steel is a general term for all kinds of non-metallic particles entrained in steel. Steel contains elements such as oxygen, nitrogen, and sulfur. Their solubility in steel is high at high temperatures, but very low...

Impurities in steel can be classified according to their composition, performance, source and size. According to the composition of inclusions, the impurities in steel can be divided into three categories: oxide impurities, sulfide impuritie...

low titanium ferro phosphorus which require the content of titanium less than 2% or even less than 1%, generally the content of titanium in ferro phosphorus ranges from 0.3% to 2%....

Non-metallic phases such as oxides, sulfides, nitrides and other non-metallic phases that are produced or mixed with steel grades during smelting and pouring and cannot be eliminated after processing or heat treatment and have no contact wit...

Electrolytic manganese flakes appear like iron,irregular flakes, firm and brittle,one side is bright,the other side is rough,the color appear silver white to brown,if processing into powder,it will appear silver gray....

In industrial production,silicon carbide lumps usually use quartz,petroleum coke etc as raw materials,auxiliary recovery materials,waste materials and are prepared through grinding and other processes.........

Steel slag is a waste of steel making which produced during by separating the molten steel with impurities from steel furnace. The slag appears as a molten liquid melt and is a complex solution of silicates and oxides. The foamed slag greatl...

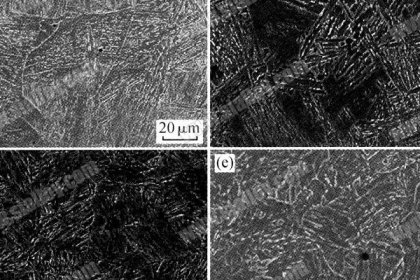

The purpose of steelmaking and slagging is to reduce the oxygen content of molten steel and desulfurize, and remove phosphorus in molten steel. In addition to controlling the FeO content, increasing the quantity of slag can also effectively...

The silicon metal always supplied with the natural lumps (size compared bigger), standard lumps and powder even micro-powder.Silicon metal is produced by reducing high-purity silica with low-ash carbonaceous reducing agent in a carbon-lined...

The requirements for oxidizing slag in the steelmaking process are: higher alkalinity, stronger oxidizability, appropriate amount of slag, good fluidity and proper foaming. Alkalinity is a measure of acidity and alkalinity of slag and is a n...

The slagging process of molten steel is to control the type and quantity of slag material and add slagging agent , so that slag has oxidation or reduction properties to meet the needs of the steelmaking reaction in the furnace. Production pr...

中文

中文